His progress this year, which resulted in an extremely close title fight with Mercedes, was largely supported by the work of engine partner Honda, which is leading the F1 title for the first time since 1991.

The most impressive thing about Honda’s form this year is how quickly its fortune has turned in F1. After the incredibly tough days with McLaren, his engine is now on a par with Mercedes – an impressive achievement.

Honda has been pretty open about the kind of changes it has made to its current power unit, and here we take a look at some of the details and why they were especially important.

At the heart of the new powerplant is a redesigned internal combustion engine that has undergone numerous changes that not only help improve combustion efficiency, but also reduce the overall size of the unit.

First up is a new cylinder coating developed by Honda’s motorcycle division and rightly called the “Kumamoto coating” because of the factory in which it was developed.

Cylinder liner coating is anything but a new idea, but that doesn’t mean you can’t still make progress in this area, especially if you transfer ideas and technologies from the generally more revving realm of motorcycles to another project.

This new cylinder coating helps reduce temperatures and friction, which allowed the F1 department to rethink the engine block design parameters as they could now run the engine harder for longer.

Honda RA620H vs RA621H cylinder spacing

Photo by: Matthew Somerfield

This had a dramatic impact as the design team was able to reduce the overall size of the ICE. Not only did this lower the crankshaft position to improve the CoG, but it also coincided with a more compact layout which resulted in the design team adjusting the hole pitch.

This essentially allowed Honda to move the cylinders closer together without fear of compromising the integrity of the cylinders. This has resulted in a shorter and narrower cylinder head.

As can be seen in the figure (above), moving the cylinders together can also reduce the overall size of the cylinder head.

The design team also took this as an opportunity to deal with the ICE lean offset, as the RA620H with a front left bench (top left) was replaced with a right-handed arrangement for the RA621H (top right).

This has made it possible to repackage some of the other engine elements and accessories while changing the overall balance.

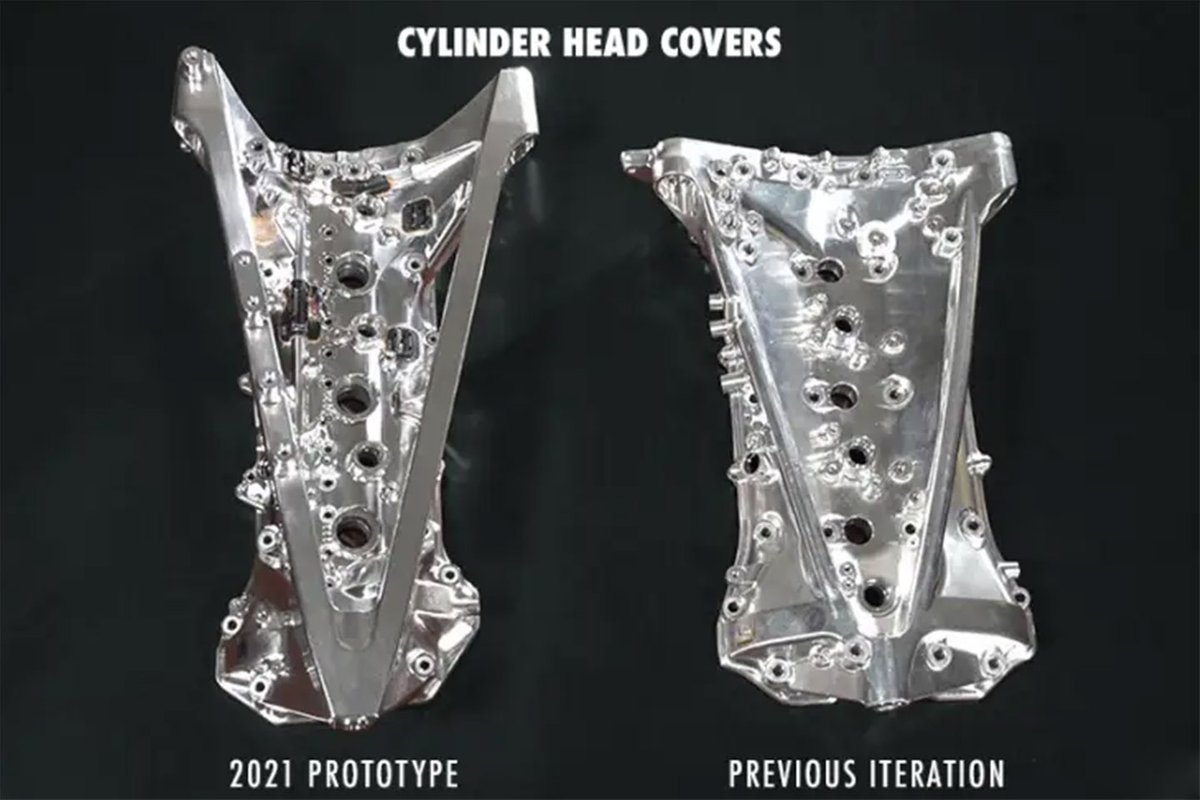

Engine cylinder head covers

Photo by: Honda

As a result of these dimensional changes to the cylinder head, the cylinder head cover has also undergone a dramatic redesign. This becomes clear when the cylinder head cover on the RA620H is compared to a prototype for the RA621H in a picture released by Honda earlier this year.

The only thing the two covers have in common is the assembly frame for the unit, the position of which is regulated by the regulations.

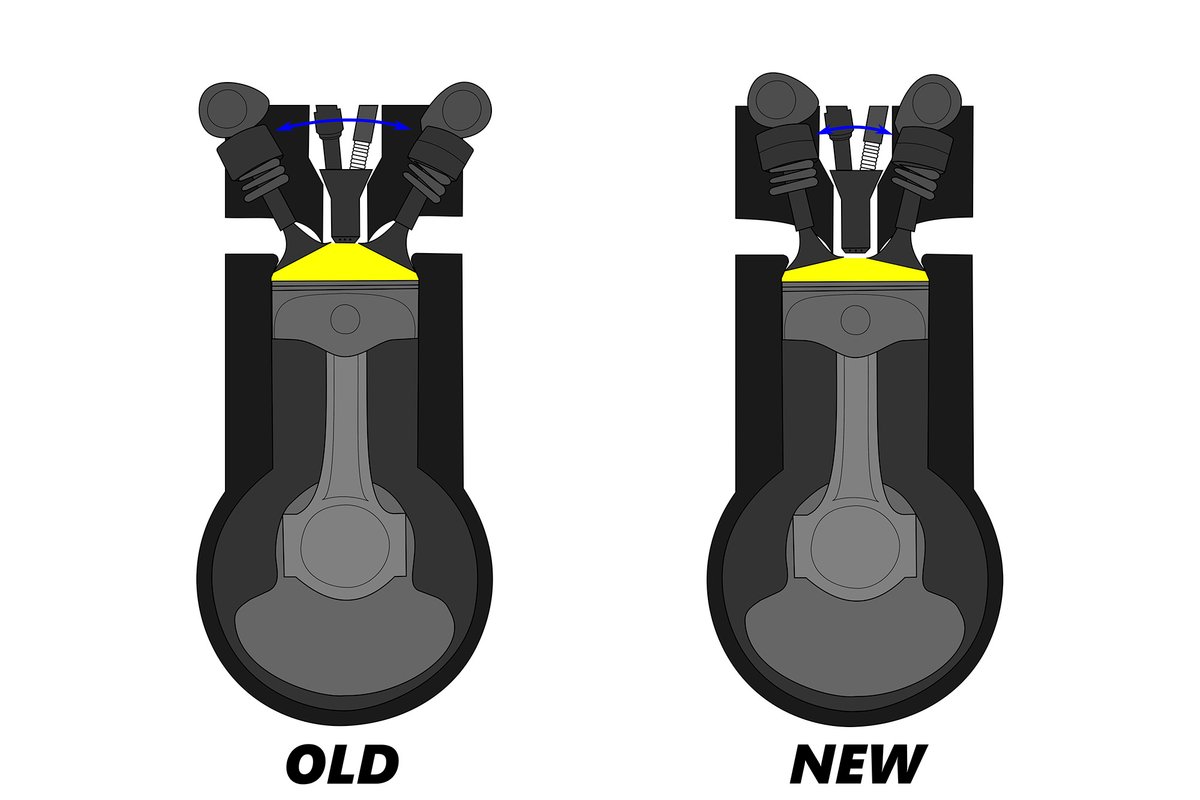

If you look at the cylinder head cover from one end (below), not only does the shape differ between the two specifications due to the mounting on the head, but the distance between the cams has also been massively reduced, which changes the valve and displaces it.

Honda Powerunit CAM distance comparison

Photo by: Matthew Somerfield

Changing the valve angle also changes the flow angle into the cylinder, which has probably been countered by further changes to the design of the valves and the inlet and outlet openings.

But perhaps more importantly, all of these changes resulted in a higher compression ratio. This likely changed the piston crown design as well.

Honda valve assembly

Photo by: Matthew Somerfield

However, the changes to increase compression ratio and combustion efficiency have a downside as the amount of exhaust energy generated is reduced, resulting in less electrical energy being recovered by the MGU-H, which obviously leaves a deficit in service.

To counteract this, Honda has also redesigned parts of its turbocharger and once again supported another department in the company.

HondaJet assisted the Formula 1 division with the move to the larger, outboard-mounted compressor and turbine in 2017 and was perfectly positioned to revamp the shape of the turbocharger’s impellers to compensate for the lower flow volume.

Change of direction

Why did Honda feel compelled to revise its engine design, especially since it had already approached a similar level of performance as Mercedes by 2020?

The answer lies in the fact that Honda’s previous units placed a greater burden on the recovery and use of electrical energy, which resulted in the loss of combustion efficiency.

FIA technical guidelines before and during the 2020 season nullified these strategies and undermined any performance gains that would have been possible with a future development program geared towards them.

Honda, which had already planned to launch a new power unit for 2021 before deciding to postpone the plan, therefore decided to undo its actions and push the new design forward again.

This will give it an even better understanding of the new engine design ahead of the launch of E10 fuels in 2022, which it continues to work with Red Bull despite the impending withdrawal from Formula 1.

More or less

One of the major consequences of downsizing the engine and lowering the center of gravity is the power gained on the landing gear side, which is even more important given the homologation stop this season.

This has undoubtedly helped both AlphaTauri and Red Bull move forward compared to last season and has resulted in a much tighter rear end of both cars.

The aero departments were therefore able to use the narrower housing of the units and the apparently lower cooling requirement.

Max Verstappen, Red Bull Racing RB16B

Photo by: Charles Coates / Motorsport Images

Obviously, comparisons can be drawn here with Honda’s return to the sport in 2015, with McLaren’s claims of a “size zero” tail now finally being realized.

And while many suspected the Japanese manufacturer might end its development spurt after closing the gap with Mercedes last year, the exact opposite was the case. It has worked diligently to accelerate past Ferrari and Renault on the way to its ultimate destination.

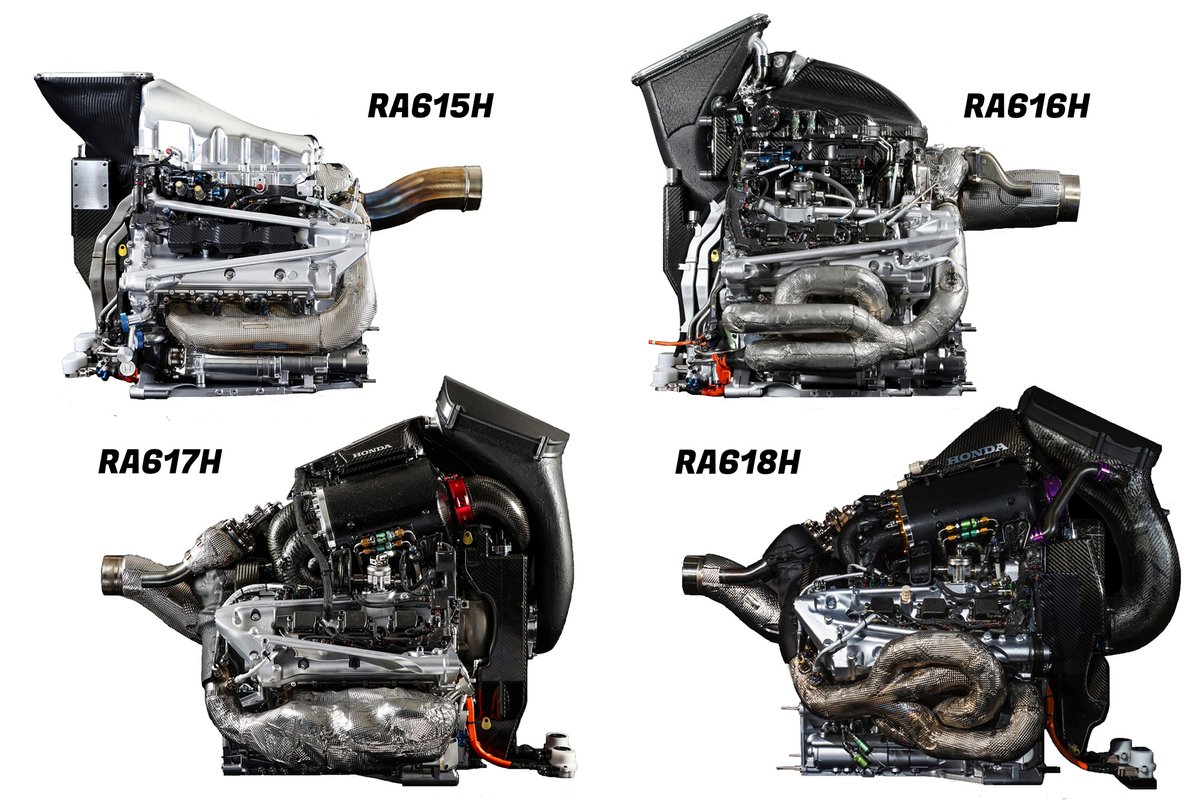

Historical development

However, Honda’s advance has not been without its difficulties and the power unit has undergone numerous transformations along the way.

The RA615H had a split turbocharger arrangement, similar to that introduced by Mercedes a year earlier, but to keep the silhouette of the unit as small as possible, the compressor and turbine were also housed within the V of the engine.

A low-line intake plenum and log-style manifold are just two of the other standout features designed to keep the power unit as small as possible to aid McLaren in their quest for a smaller, more aerodynamic rear end to theirs Automobile.

The RA616H was a further development of its ancestor, as the Japanese manufacturer was limited in terms of architecture and at the same time tried to take into account the goals of its partner McLaren.

However, in order to make a profit, a conventional multi-branch exhaust manifold was used. The inlet plenum has also been enlarged, and the overall design of most aspects of the unit has been enlarged slightly to allow for more leeway for durability – a major issue in the first season.

Honda power unit 2015-2018

Photo by: Matthew Somerfield

In 2017, Honda made its first major layout change to address some of the major drawbacks to its original design.

Honda kept the split-turbo approach, but instead of being completely housed in the V, it switched to a design closer to Mercedes, with the turbine and compressor mounted on either end of the engine.

This so-called “pancake” arrangement gave Honda more leeway in terms of turbo design, but it also caused more technical headaches as the connecting shaft and MGU-H had to be redesigned to accommodate the greater distance between the turbines and Compressor.

The combustion chamber design was also changed in this redesign and you can see once again that the intake manifold and the exhaust system have been adjusted in a correlated manner. Despite these significant changes, the 2017 engine’s overall performance was actually in decline compared to its predecessor, which became the straw that broke the camel’s back in its relationship with McLaren.

Nevertheless, this transition was necessary despite the reduction in output, as the previous design had reached a dead end. But Honda’s move to Toro Rosso turned out to be a turning point in its F1 fate.

Toro Rosso STR13

Photo by: Giorgio Piola

The RA618H continued to build on the fundamentals of last season’s engine redesign, with many changes under the hood and the usual redesign of the intake plenum and exhaust.

Meanwhile, Honda and Toro Rosso have also worked on the installation, as the former made concessions on changing the position of the boost piping, while Toro Rosso installed a “saddle” radiator over the power unit, much like McLaren had done done this in previous years.

The RA619H was to be the first Honda powerplant installed on more than one team, and while the relationship with Toro Rosso was good, having Red Bull on board would bring with it greater expectation.

With the RA619H and the subsequent RA620H, Honda was able to collect twice as much data and use it to make steady strides in terms of performance and durability before making the key changes we already outlined for 2021.

The post How Honda turned its engine into a Mercedes racket first appeared on monter-une-startup.Did you miss our previous article...

https://formulaone.news/ferrari/watch-sainz-is-trolling-leclerc-for-being-on-the-f1-plane-to-baku-fucked-up