Königsegg

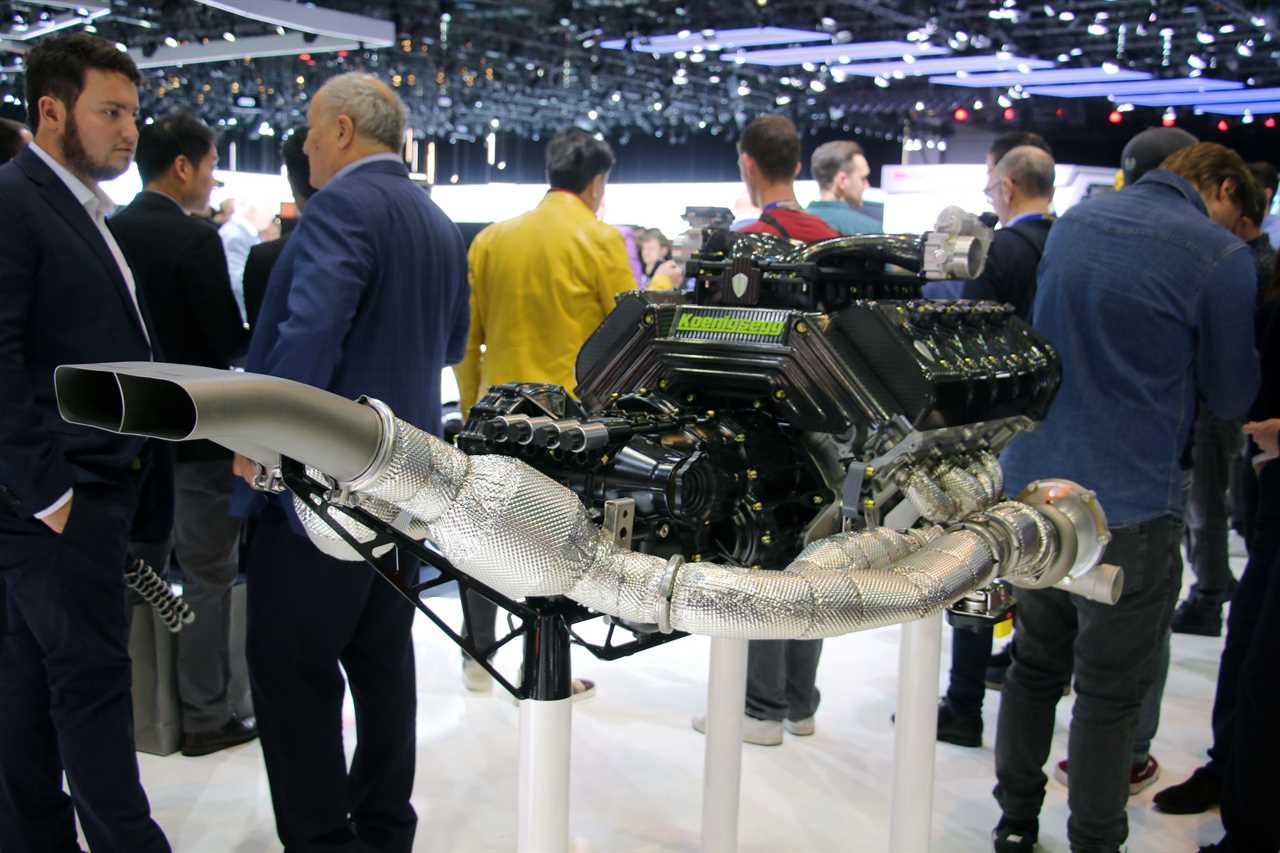

The 5.1-liter twin-turbo V-8 that powers the Koenigsegg Jesko is possibly the fastest rotating engine that has ever been installed in a production vehicle. But, according to founder Christian von Koenigsegg, that wasn’t even a goal the engineers had in mind when developing this engine.

“Engine speed” is the speed at which an unloaded combustion engine can increase the speed. It’s a statistic that most automakers don’t want to publish. The last time the topic came up was over a decade ago, with the glorious Yamaha-built V-10 that powers the Lexus LFA – a car that needs a digital tachometer to keep up with its revving engine that could go from idle to 9000 rpm in 0.6 seconds, a recording speed of 15,000 rpm per second.

Today, Koenigsegg’s data shows that the company’s latest V-8 has an average pick-up speed of 31,700 rpm, with peak pick-up at an almost staggering 46,000 rpm in the mid-range engine speed. This is wild and, as far as we can tell, an all-time record for road car engines.

Königsegg

The funny thing is, the company didn’t even bother with the pickup speed of its new engine until Gordon Murray Automotive started talking about the stats in August 2020. The British supercar startup, founded by (and named after) the man behind the McLaren F1 claimed its 4.0-liter naturally aspirated V-12, built by Cosworth, had a pick-up speed of 28,400 rpm and walk from idle to red in a breathtaking 0.3 seconds.

But when Koenigsegg engineers examined the revving ability of their own engine, they found that the Jesko engine was beating GMA’s Cosworth V-12. “The Gordon Murray car is the only reference we’ve heard of,” Christian von Koenigsegg told Road & Track. “As they were very proud of it, an engineer came up to me and said, ‘Christian, you know that we are much better.’ I said really? If it’s such a big deal, maybe we should mention it. “

According to von Koenigsegg, the decisive factor that makes the Jesko engine turn faster than the GMA is not in the engine – it’s the gearbox. Murray’s car uses a special Xtrac six-speed manual transmission with a thin titanium disc in place of a traditional flywheel and three-disc clutch. This setup enables the engine to respond so quickly that GMA had to install complex software for speed adjustment in order to enable smoother driving.

Königsegg

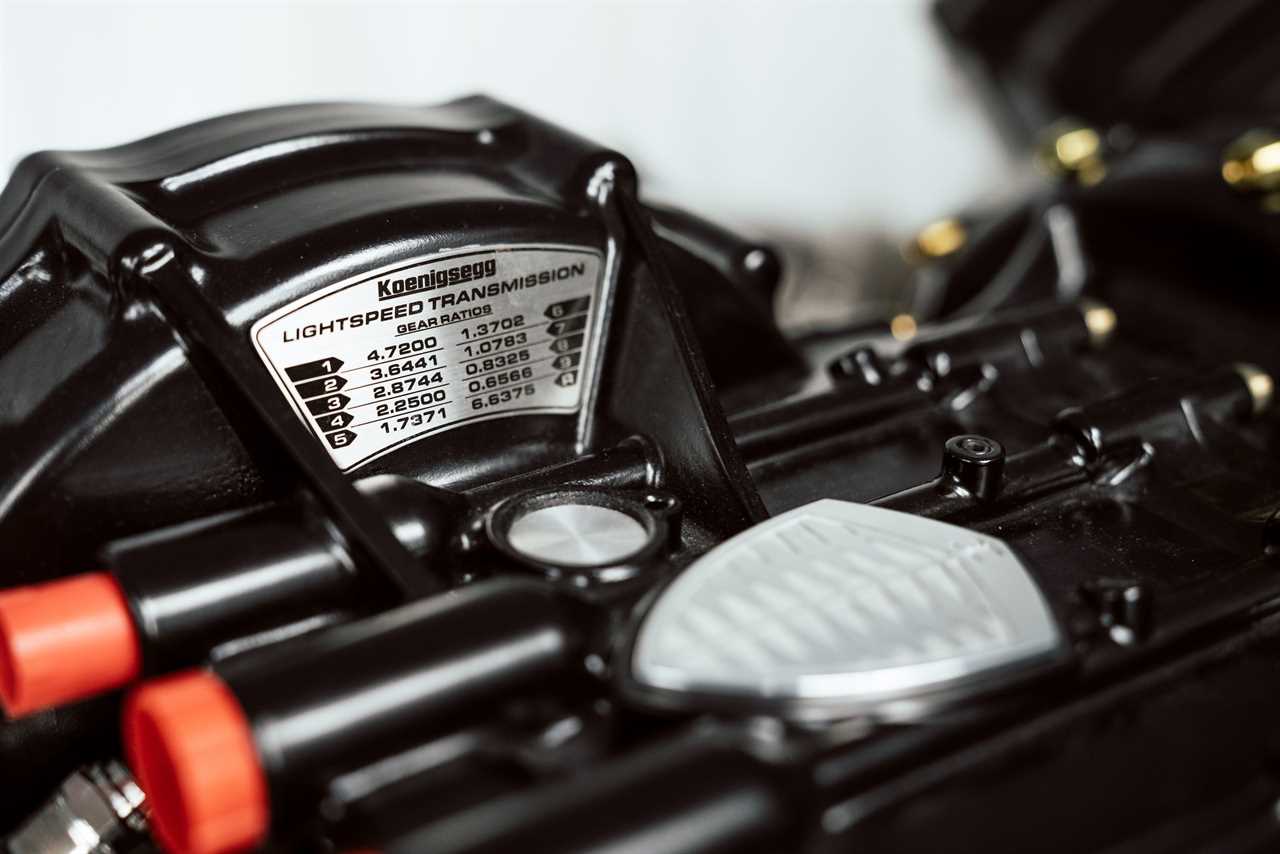

But the Jesko has no flywheel, no clutch and no synchronization in the gearbox. The Lightspeed transmission has nine forward gears; It’s built into the engine block, weighs 198 pounds, and can handle more than 1100 lb-ft of torque. Instead of a conventional clutch mechanism between the engine and transmission, the Lightspeed transmission has seven wet clutches in its aluminum housing and an eighth for the electronically controlled differential.

The completely unconventional transmission design enables capabilities never seen before in road vehicles. In the Jesko you can shift from any gear directly to any other gear almost instantly. A double tap on the gear selector switch automatically switches you back to the lowest possible gear at any speed in order to achieve maximum acceleration.

Due to the way the gearbox works, no speed adjustment is required. “We can use the gearbox to force the engine to change speed more quickly, which is not possible with synchros,” says von Koenigsegg. “In addition, with nine gears you have super-short gear ratios. It’s really a nice, motorcycle-like narrow passage. I had high expectations but I was really blown away in terms of engagement and response how it just does exactly what you want right away. “

This content is imported from YouTube. You may find the same content in a different format or more information on their website.

Von Koenigsegg says his team never focused on the engine’s pickup speed. Removing the flywheel and clutch helped make the drivetrain lighter and more compact – the insane ability to increase speed was a side effect. “It’s pretty wild,” says von Koenigsegg. “I’ve never seen an engine without a flywheel, but it just worked perfectly – first in the simulation, then in reality.”

The GMA T.50 is known to be one of the last naturally aspirated super sports cars available today. Murray is decidedly against turbochargers – he once compared the response behavior of turbo engines to “watching the paint dry”. The Koenigsegg twin-turbo V-8 clearly doesn’t suffer from this trait, and the man behind the brand wanted to explain why.

“Turbos have no influence on the response behavior of an engine per se,” says von Koenigsegg. “Turbo engines tend to have heavier components inside. Of course, when you have enormous turbo you have a delay in boost that is different from the engine’s pick-up speed. “

Maté Petrány

Von Koenigsegg admits that in the Jesko you can experience a gradual increase in thrust under very special driving conditions. Cruising in ninth gear at 1700 rpm? Yes, when you put it on the floor you won’t feel most of the thrust until around 3000 RPM. “But if you pull the gearshift lever instead and accelerate from 1700 rpm to 7000 rpm in no time at all, there is no lag. In any case, you can drive it with the feeling of not having any turbos at all, of having full power all the time. “

The result seems to have taken the Swedish supercar company founder by surprise. “We expected great responsiveness as we don’t have a flywheel or clutch and it seems faster than anything else we know. The feeling is electrifying. I continue to use the word ‘synaptic’. It’s like, you think of speeds, you got it. There is no delay. It’s just there, instantly. It’s very cool. “

When idling, the Jesko V-8 is limited to 7800 rpm, which increases to 8500 rpm when in gear. To ensure maximum clout at all times, Koenigsegg added a patent-pending air injection system that uses a small electric compressor to fire precisely timed 290 psi blasts of air directly into the turbochargers and fast-forward them to avoid delays.

Königsegg

The engine that powers the Jesko is actually a further development of the V-8 in the Agera RS. With a displacement of less than 5.1 liters, it is a flat crank design with dry sump lubrication. Since this is a long stroke motor, the Koenigsegg team had to think carefully about vibrations when it reached that 8,500 rpm redline. The connecting rods are made from Swedish alloy steel, not the titanium from the Agera RS – but weighing just 1.19 pounds each, the new material provides extra strength without any weight loss. The pistons weigh 0.63 pounds each and have a ceramic coating that prevents hot spots from developing under heavy engine loads. Each cylinder has a pressure sensor and two injection nozzles; a third injector is located in the intake chamber above each cylinder. The Jesko V-8 develops 1280 HP on pump gas; switch to E85 and that number increases to 1600.

Koenigsegg is one of the most extreme examples of an automaker on the planet. The multi-million dollar hypercars that leave the brand’s factories have outrageous technical solutions that cannot be found in any other vehicle. This was only the first part of our in-depth conversation with von Koenigsegg – stay tuned for more for the next few days.

Königsegg

The post How Koenigsegg built the fastest rotating engine in history first appeared on monter-une-startup.Did you miss our previous article...

https://formulaone.news/mclaren/alonso-vettel-will-miss-the-outstanding-raikkonen-when-he-leaves-f1